Original from Europe from 2002 ,with over 290 plastic recycling projects currently in operation, GET recycling gives you a clear advice with a tailor made solution on the basis of your plastics and requirements.

High efficiency at high capacities,high quality standard recycling plant at reasonable investment,GET recycling equipment and lines support operational excellence and economic performance for each customer.

GET is one of your ideal partners in the field of recycling from beginning of negotiation to seeking for best solutions, and from machines manufacturing to after-sales service.

PS/ABS recycling line: for electronic and household appliances plastic waste recycling, to get PS, ABS scraps.

GET’s PS/ABS recycling line takes use of density separation (salt water)to get high purity PS and ABS materials with Stable performance. Salt water treatment system is equipped to reuse the salt water.

Plastic film is valuable secondary resources in recycling market, recycled film can be used to produce wide range of produces.

The waste plastic film to be in different conditions in terms of humlity,contaimination,form.

The film in recycling market is basically divided into the following families:

Agricultures film: including greanhouse, mulching,tunel and banana film.

Post consumer film: including film form landfills and selective collections.

Post-consumercial and post- industrial film:including materials 100% stretch.

Pulp-film: including paper factory waste,paper cup, paper-plastic box.

For film recycling industry, GET recycling can offers a series of well-devoloped recycling lines for efficient recycling of all kinds of film materials.

Pulp film recycling line is mainly aimed at processing waste plastic film of paper mill, waste material of paper mill, paper mill braid material, stirring rope material and other PP/PE waste plastic. For the paper mill waste plastic because of its large capacity of complex tissue composition, high impurity content of pulp, iron metal content of high characteristics of design and development.

Customized solutions provided by GET recycling, which can separate pulp and plastic. Pulp can be extruded into cake and returned to the paper mill for application, while plastic can make pellets into finished products. The whole line has a high level of automation, and the design of large output is associated with energy saving and consumption reduction and can effectively improve the quality of finished products.

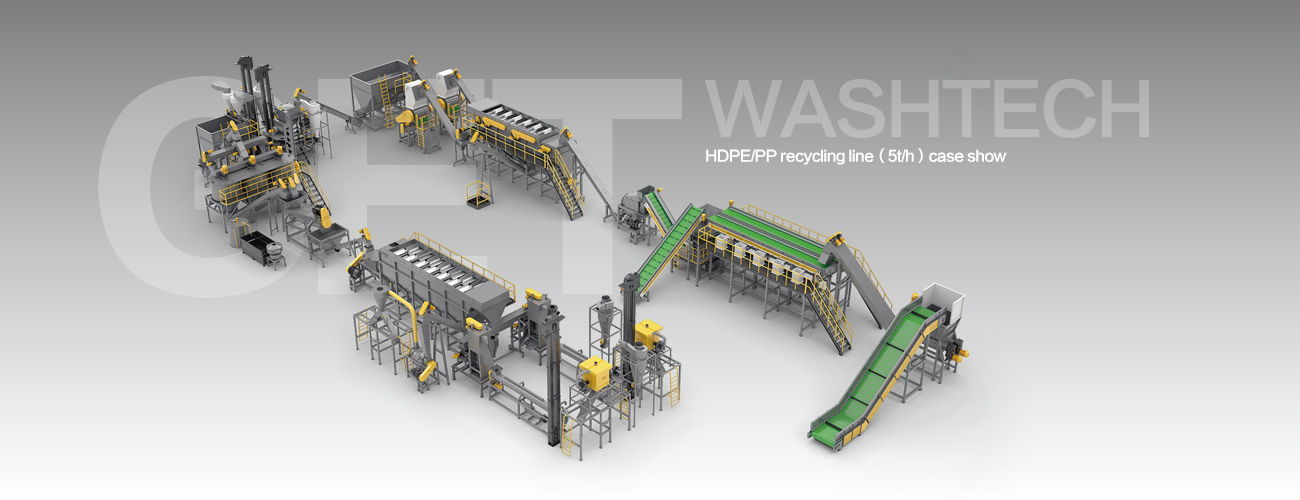

In the field of the recycling plants for HDPE and PP materials coming from urban and industrial collection sites, the HDPE and PP waste vary significantly from country to country, but also within the same country. Also the HDPE and PP materials has different size from small to big:

HDPE /PP bottles and containers,

HDPE /PP barrels and boxes

HDPE /PP chairs,desk, pipes

GET has developed HDPE recycling line continuously, a series of modular components can be provided to match the different features of HDPE/PP materials.

With GET’s tailor made recycling solutions, the most of the worst contaminants are eliminated in early step to reach the best final flakes quality with low consumption.