|

|

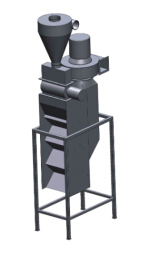

Introduction of Zigzag

The Zig Zag also known as an Air Classifier, is designed to remove light contamination; such as paper,label and dust from plastic flake or other granular material. Single or multiple tower systems are available dependent on the throughput required. Typically positioned in a recycling line after granulation or dry cleaning operations. an aspirator is used to remove the lighter particles from the main material flow.

The Air Classifier Separator works on the principle of upward vacuum extraction of light contaminating materials by a channel, into which the mixed material falls. Material enters the Air Classifier Separator via a rotary valve and is distributed evenly between the towers before tumbling down each zig zag chamber. The heavy fraction is removed from a central collection hopper and the light fraction is lifted from the cascading material stream by a counter air flow and transferred to a separating cyclone.

will not mixed after separating.

|