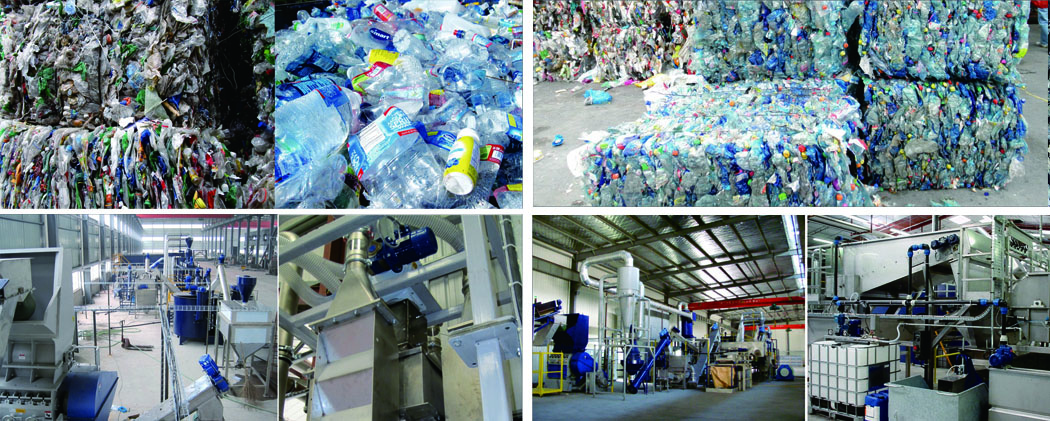

PET bottles recycling becomes an economic opportunity even when the raw material prices are low. with more than 10 years of experience in PET recycling worldwide, GET provided that the recycling plant is carefully designed with aim to minimize the operation costs and obtain first-quality PET flakes.

From the long experience gained in manufacturing of a large number of recycling lines, and detailed user feedbacks for all kinds of PET bottles recycling, GET improved the PET recycling solutions continually, granting to the customers both output capacity and flakes quality and low operation costs of the recycling line.

The flakes produced are suitable for the following applications:

Bottle to Bottle

Bottle to Packaging

Bottle to Fibers

Bottle to Sheet

Bottle to Strapping

Standard output: 1000, 2000, 3000, 4000,5000 kg/h

Typical Process

Estimated plant parameters

|

Model

|

Capacity (output)

|

Power installed

|

Area

|

Steam

|

Compressed Air

|

Water supply

|

|

PET10

|

1000kg/h

|

220kw

|

250m^2

|

4000kcal

|

0.5m^3

|

2m^3

|

|

PET20

|

2000kg/h

|

260kw

|

350m^2

|

6000 kcal

|

0.5m^3

|

3m^3

|

|

PET30

|

3000kg/h

|

380kw

|

500m^2

|

8000kcal

|

1m^3

|

4.5m^3

|

|

PET50

|

4000kg/h

|

500kw

|

700m^2

|

10000 kcal

|

1m^3

|

6m^3

|

Unit consumption

|

No.

|

Item

|

Average consumption per ton flakes

|

No.

|

Item

|

Average consumption per ton flakes

|

|

1.

|

Electricity

|

70-90kw

|

3.

|

Washing detergent

|

4-8kg

|

|

2.

|

Steam

|

250-400kg

|

4.

|

Water

|

1-1.5T

|

Flakes quality reference table

|

No.

|

Description

|

AA level(ppm)

|

A level(ppm)

|

|

01

|

PVC content

|

¡Ü25

|

¡Ü100

|

|

02

|

PE/PP/colored flakes/metal/others

|

¡Ü75

|

¡Ü100

|

|

03

|

Total impurity

|

¡Ü100

|

¡Ü200

|

Factory management will afferect the PVC content

|